What materials are used in FPC production?

- Liu Mao

- Jul 13, 2020

- 2 min read

Flex PCB are flexible printed circuit boards that are used in applications where is small and irregular spaces.

FPC is made up with serveral major parts as below

Isolating membrane

Isolating membrane (film) is the base layer of flex circuit, copper foil are adhered to isolating layer. In multilayer FPC, the membrane is adhered to inner layers. It also function as protective covering, to isolate circuits away from dust and humidity. The isolating membrane can also reduce the stress when the FPC is curved or bended.

In some of the flex PCB, there are rigid parts that are made with aluminum or steel, to provide accurate dimension of the boards and physical support of components and wires. Adhensives connect rigid parts to flex parts.

Conducting layer

copper foil are used in flex circuits and can be processed with ED or plating. Copper made with ED processing are with brighter surface and the other side could be matt.

ED copper foil is very flexible and can be made to a big range of thickness and width, the matte side needs to have a special treatment to improve its ability of adhere to other layers.

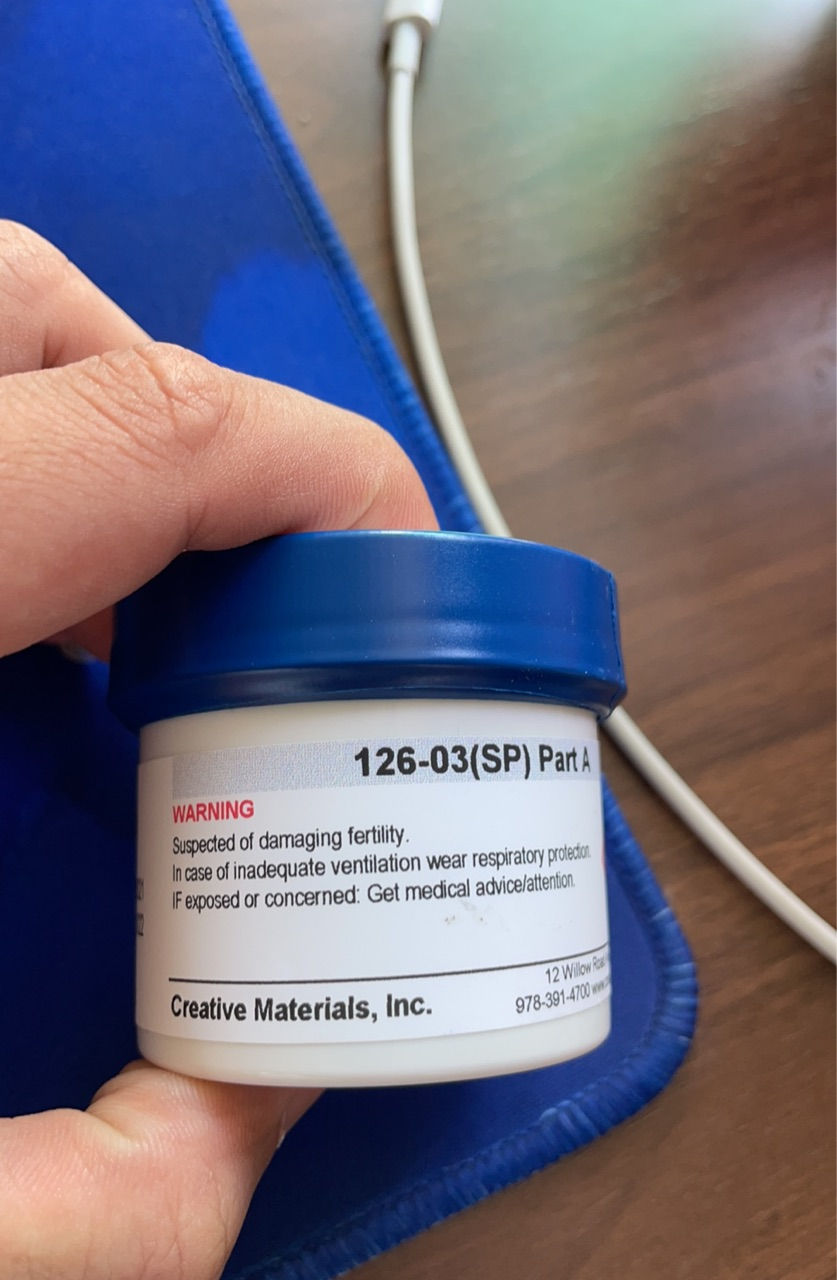

Adhensives

Adhensive, its main function is to connects isolating membrane to conducting layer, can also be used as covering layer for surface protection, or for covering only.

Covering only adhensives is aiming to form a circuit in stackup while the protection adhensive layers is made by silkscreen.

Not all stack up of FPC includes adhensives, those flex PCB without adhensive are with more flexiblity and thinner thickness. It has better heat conducting rate, which is more suitable for some special enviorments.

Chee mau is a professional flex circuits manufacturer, please send us your inquiry here.

Comments