FPC Introductions

- Apr 18, 2019

- 2 min read

1. General Introductions

FPC stands for Flex Printed Circuit.

It is a conducting circuit pattern on flexible laminate made by optical pattern transferring and etching process. The outer layer are connected with inner layers by conducting via. in double-sided and multi-layers FPC. The circuit pattern are isolated by PI and glue layer.

FPC mainly classified by single-sided FPC, hollow out FPC, double-sided FPC, multi-layers FPC and flex-rigid board.

2. The advantages of FPC

a. small volume, light weight. Can be placed in tiny, high-density electronics.

b. flexible, bendable. Can be placed in any geometry equipment.

c. can be dynamic flexible other than static flexible.

d. can expand at 3 dimensions, increase the circuit design and industrial design possibility.

e. except working as a normal circuit board, a FPC can also be work as induction coil, electromagnetic shielding, touch switch on-off button, etc.

3. The main material for FPC

The main material for FPC is: a) substrate b) cover lay c) stiffener d) other supporting material

a. substrate

a.a) with glue layer

substrate with glue layer are composited with three parts: copper foil, glue and PI. It also divides by single layer and double-sided--depending on copper foil is one layer or two layer.

a.b) without glue layer

substrate without glue layer do not contain copper foil and PI, it is thinner, better performance on size consistency, heat resistant, chemical resistant and bend resistant. It is widely used now.

copper foil: typical copper foil includes 1oz, 1/2oz, 1/3oz, 1/4oz thickness. For line width/space less than 0.05mm, the 1/4oz copper foil will be used.

cover lay: composited by three parts: release paper, glue and PI. But only glue and PI will be left on FPC, the release layer will be peeled off during manufacturing.

c) stiffener

It is a special material for FPC, will be used in some special area to increase the strength of supporting.

Stiffener usually includes:

c.a) FR4 stiffener: composited by Fiber glass and epoxy glue, which is the same as regular rigid PCB

c.b) steel plate stiffener: make of steel with higher supporting level

c.c) PI stiffener: same as cover lay, composited by release paper, PI and glue. But the PI layer is thicker, ranges from 2mil to 9mil.

d) other supporting material

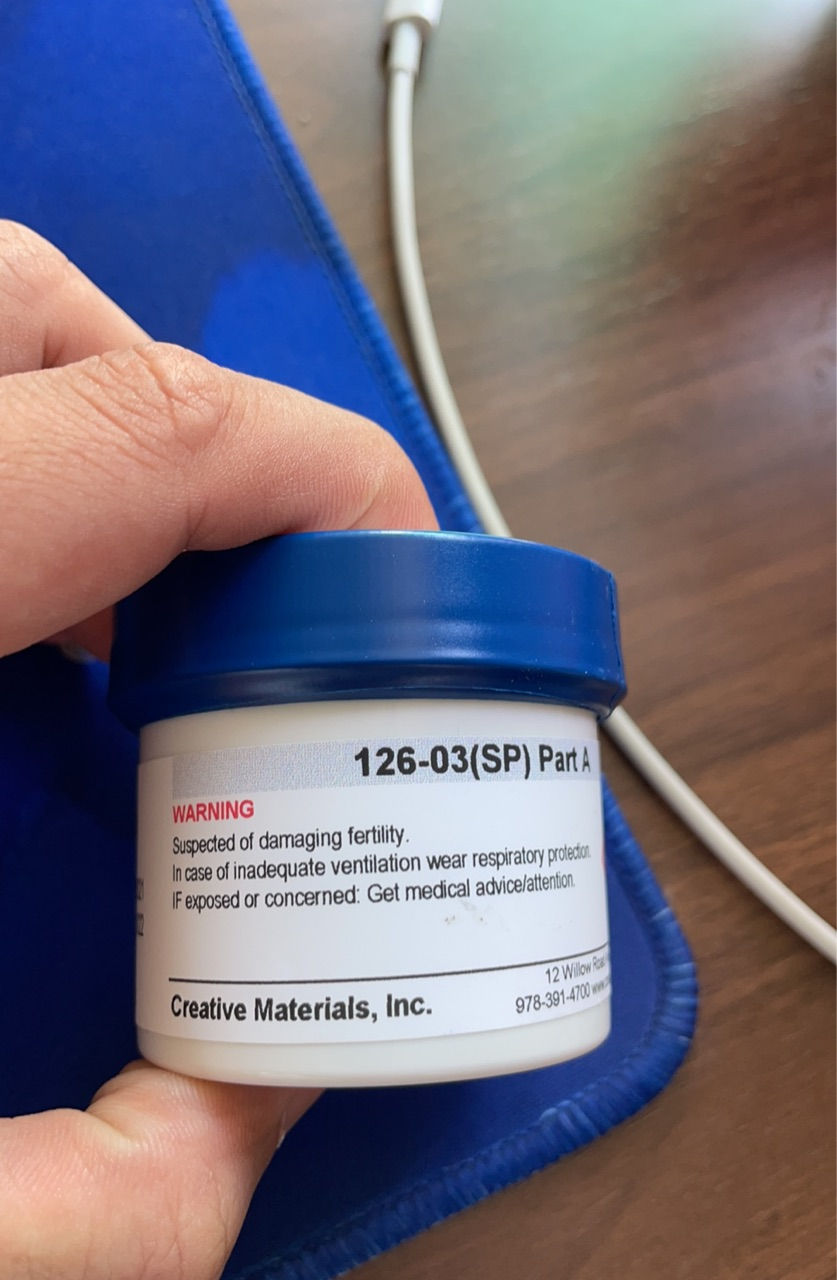

d.a) pure glue: it is used to separate and bonding layers, rigid and flex parts and FPC with stiffeners.

d.b) electromagnetic protecting layer: glued on surface work as a shield

d.c) pure copper foil: made of copper foil

4. Types of FPC

a. single layer FPC: only one side has circuit

b. double sided FPC: circuit on both sides

c. hollow out FPC: also called window FPC

d. multi-layer FPC: FPC with more than 2 layers circuits

e: rigid-flex: combination of rigid PCB and FPC

Comments